Take away message from ICCF18, THE Cold Fusion Conference.

1. Anomalous heat, with power density far beyond what can be obtained from chemical (outer electrons, burning) reactions can be obtained routinely and repeatably.

2. If it is not chemical then the energy must come from the nucleus or its constituents as is borne out by the clear detection of transmutations, even if neutrons and other high energy particles are below easily detectable (and safe) levels.

3. AHE, LENR, CF or whatever the name, is a real and imminently more useful effect than fission because it can produce the energy of fission without the dangers or pollutants.

4. Efforts are underway, worldwide, to bring the technology to market, even absent a widely accepted theory of operation, as evidenced by successful demonstrations by several companies.

5. There is no doubt that as more testable theories are proposed the 'effect' will become better understood and be optimized for a multitude of applications including energy production.

Opening Session of ICCF18 7/21/2013

All the LENR luminaries are here including Peter Hagelstein and some that I had met up at MIT's 'Cold Fusion 101' in January '13.

Peter handed me a 'LENR intro short course' sponsored by National Security Innovation Center (NSIC) that he had prepared for the early Sunday morning session that I missed. I'll be reading that until my eyes close right after this report to my friends and family.

I've got to say that the 200 or so attendees were top notch and many known to me by name and some by sight from their research, web activities, postings and previous meetings. I have the complete list so I won't mention any more names now.

A great many of the big names I spoke with had renewed confidence that Rossi's 'E-Cat' is for real after the independent testing and reporting that took place a couple of months ago. At the same time, none could confirm having achieved similar power gains (COP =6) with any consistency and duration. So my question, often repeated, was how long before someone else hits the magic formula / potion / catalyst or conditions that make LENR a viable power producing reaction? I have a few other questions that I hope to have answered this week at ICCF18. All in all a great start.

Will keep you posted.

Hi Condensed Matter Physics or Anomalous Heat Effects (AHE) or LENR or Cold Fusion etc. etc. followers,

No I'm not making light. This stuff is serious. Ten to twelve hours a day spent at Mizzou U and I've already got a serious headache trying to wrap my head around all I've learned. Talking ( which is not my strong suit) and listening to many scientists here, I've learned a lot about the discontinuities in the thinking about an appropriate theory that covers all the observed phenomenon. I watched the live feed from the Defkalion demonstration where the input was about 1900 Watts and the output was 5800 Watts! OK, maybe not as impressive as a gain of 6 or 60 that others have claimed but impressive to put on this kind of demonstration at this venue of 200 + knowledgable people in the field. Defkalion said they will make all the data publicly available. I have no doubt that if there is anything deceptive going on, this bunch will be all over it in a nano second.

Another long, exciting day tomorrow. Will tour the Nano Tech facility at 4:15 tomorrow and the SKINR (LENR, AHE) labs at 11 on Thursday. Best of all are the in-depth one on one 'poster board' discussions where all related and even remotely related questions are discussed.

More impressions from ICCF 18 in Columbia Mo. 7/2013 and some links.

A very impressive group of

researchers, scientists and engineers meeting to advance the cleanest, safest form of

energy ever discovered. Nearly as powerful as fission or fusion, these Anomalous Heat Effects, (AHE) discovered over 24 years ago by chemists Fleischmann and Pons, were largely ignored at the time because there appeared to be no immediate way to create military weaponry (explosions with fallout and deadly radiation) using the clean, 'atomic weak force'. Now, after nearly a quarter century, we are about to exploit AHE to solve the bigger problems threatening to destroy us all.

AHE also known as LENR (Low Energy Nuclear Reactions) and cold fusion still has a huge image problem with the general public which will need to be addressed. When we can buy a hot

water heater that uses no fossil fuel and very little electricity (less than a 50 Watt light bulb on average) and with that (and a $50 nickel and hydrogen fuel cartridge) heat your whole house for a year and give you copious hot water as well, the image problem will disappear.

The next hurtle for this to happen is regulatory (UL, CE) approvals and certifications. This being a brand new technology for home use, with a poorly chosen name and lots of vested fossil fueled interests... well, you can see that this will take a little longer even though similar

devices already exist and are being

tested with positive

results.

Someone commented that the tools to be able to elucidate LENR phenomenon are just now being developed. I think this is only half the reason for the lethargy in LENR R and D.

It is not so much that research tools are lacking, it is more that the young scientists with the energy and zeal to apply them are absent. This became clear to me as I scanned the auditorium at ICCF18. My guess is that the average age of the 200+ attendees was somewhat past retirement age. Our educational system and the way we fund it may be the cause. Hopefully, renewed emphasis on Science, Technology, Engineering and Math (STEM) will help reverse this, but only if we are willing to fund education more equitably, not based on local wealth.

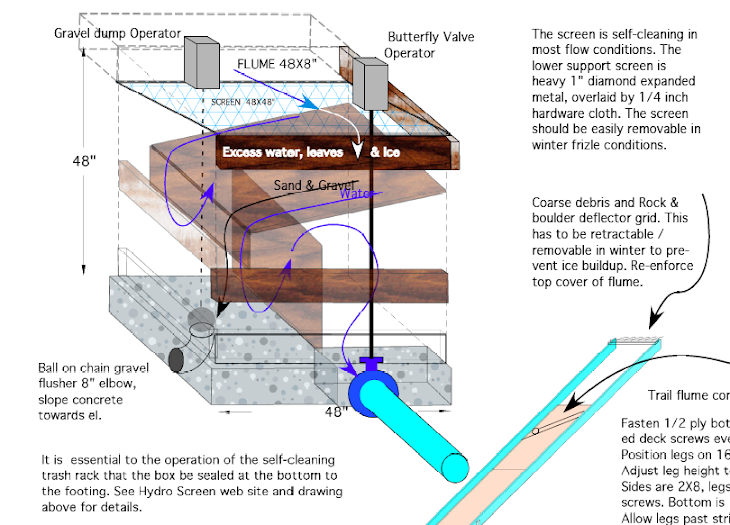

The Defkalion Reactor Cross Section 195mm X 213mm, 6KW heat output